Search

What Are You Looking For?

What Are You Looking For?

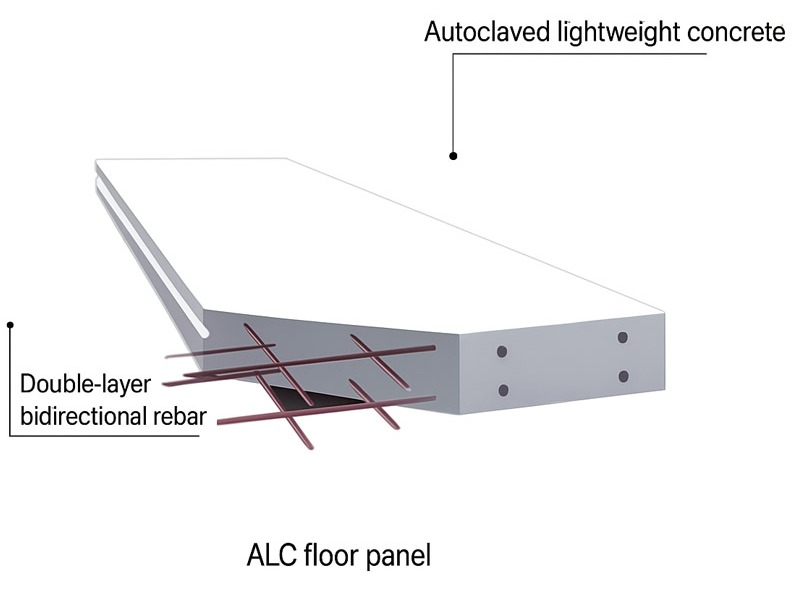

The ALC Floor Panel, is a high-performance building material designed for modern prefabricated, modular, and steel structure buildings.

Our ALC Floor Panels are manufactured under high-temperature and high-pressure autoclaving, offers excellent strength-to-weight ratio, superior thermal insulation, fire resistance, and fast installation, ideal for sustainable and efficient construction projects.

| Product Name | ALC Floor Panel, Autoclaved Lightweight Concrete Slab |

| Density | 500–700 kg/m³ |

| Panel Thickness | 75 mm / 100 mm / 125 mm / 150 mm (customizable) |

| Reinforcement | Double-layer Bidirectional Steel Mesh |

| Service Life | 50 Years or More |

Customized ALC Floor Slab for Prefabricated Buildings

Product Details:

The ALC floor panel consists of two main components: Autoclaved Lightweight Concrete (ALC): Made from quartz sand, cement, lime, and aluminum powder, cured under autoclave steam pressure. It provides excellent load-bearing capacity and thermal insulation.

Double-layer Bidirectional Rebar: Reinforced with steel mesh in two directions, ensuring enhanced tensile strength, flexural resistance, and long-term stability.

Specifications:

| Item | Parameter |

| Product Name | ALC Floor Panel, Autoclaved Lightweight Concrete Slab |

| Density | 500–700 kg/m³ |

| Compressive Strength | ≥ 4.0 MPa |

| Bending Strength | ≥ 1.5 MPa |

| Thermal Conductivity | ≤ 0.13 W/(m·K) |

| Sound Insulation | ≥ 40 dB |

| Fire Resistance | 3–4 Hours |

| Panel Thickness | 75 mm / 100 mm / 125 mm / 150 mm (customizable) |

| Panel Length | Up to 4.8 m |

| Reinforcement | Double-layer Bidirectional Steel Mesh |

| Installation Method | Prefabricated Assembly / Dry Construction |

| Service Life | 50 Years or More |

Key Features & Advantages:

| Feature | Description |

| Lightweight Yet Strong | Reduces building load by 40–50% compared to traditional concrete slabs while maintaining excellent strength and rigidity. |

| High Fire Resistance | Made from inorganic materials; achieves up to 4-hour fire rating, ideal for safety-critical buildings. |

| Thermal & Acoustic Insulation | Porous structure offers excellent heat insulation and sound absorption, enhancing indoor comfort. |

| Fast Installation | Prefabricated panel design ensures quick and clean construction with minimal on-site labor. |

| Waterproof & Moisture-Proof | Stable structure resists water absorption, cracking, and deformation even in humid environments. |

| Sustainable & Eco-Friendly | 100% non-toxic and recyclable material, supporting green building standards. |

FAQ

1. Can ALC floor slabs be customized according to project requirements?

Yes. We provide customized ALC floor slabs with adjustable thickness, length, reinforcement type, and surface treatment to meet different architectural and structural design needs. OEM/ODM services are also available.

2. How are ALC floor slabs installed in prefabricated or modular buildings?

The slabs are pre-engineered for easy installation and can be directly fixed onto steel or concrete structures using embedded connectors. We supply detailed installation drawings and technical support for smooth on-site assembly.

3. Are ALC floor slabs suitable for both residential and commercial projects?

Absolutely. Our customized ALC slabs are widely used in residential houses, hotels, schools, hospitals, and office buildings. They offer long-lasting performance and meet modern green building standards for energy efficiency and sustainability.

Looking for a Reliable ALC Floor Panel Supplier from China?

Anhui Construction Intelligent Manufacturing Group provides high-quality, fire-resistant, and lightweight ALC concrete slabs for global projects.

? Get a Free Quote and Technical Consultation Today!

Tags :

leave a message

Scan to Wechat/Whatsapp: