Search

What Are You Looking For?

What Are You Looking For?

We provide Prefabricated Steel Structure Building solutions.

Our ALC wall panels are made from a blend of cement, lime, quartz sand, and aluminum powder, the panel is autoclaved under high temperature and pressure, forming a lightweight yet durable structure reinforced with double-layer bidirectional steel mesh.

Key Features:

Customized ALC Wall Panel for Modular Buildings

Our ALC Wall Panels achieve high energy efficiency and comfort indoors, compliant with international standards for green construction, help construction save time and reduce foundation load.

Specifications

| Item | Parameter |

| Product Name | ALC Wall Panel / Autoclaved Lightweight Concrete Wall Panel |

| Density | 500 – 700 kg/m³ |

| Compressive Strength | ≥ 4.0 MPa |

| Bending Strength | ≥ 1.5 MPa |

| Thermal Conductivity | ≤ 0.13 W/(m·K) |

| Sound Insulation | ≥ 40 dB |

| Fire Resistance | 3 – 4 Hours |

| Panel Thickness | 75 mm / 100 mm / 125 mm / 150 mm / 200 mm |

| Length | Up to 6,000 mm |

| Width | 600 mm standard |

| Reinforcement | Double-layer bidirectional rebar (hot-dip galvanized) |

| Installation Method | Prefabricated assembly |

| Service Life | 50 Years or More |

Applications

This eco friendly ALC Wall Panel always apply for residential, commercial, and industrial buildings, significantly improving construction efficiency and sustainability.

Why Choose us

Honor and certifications:

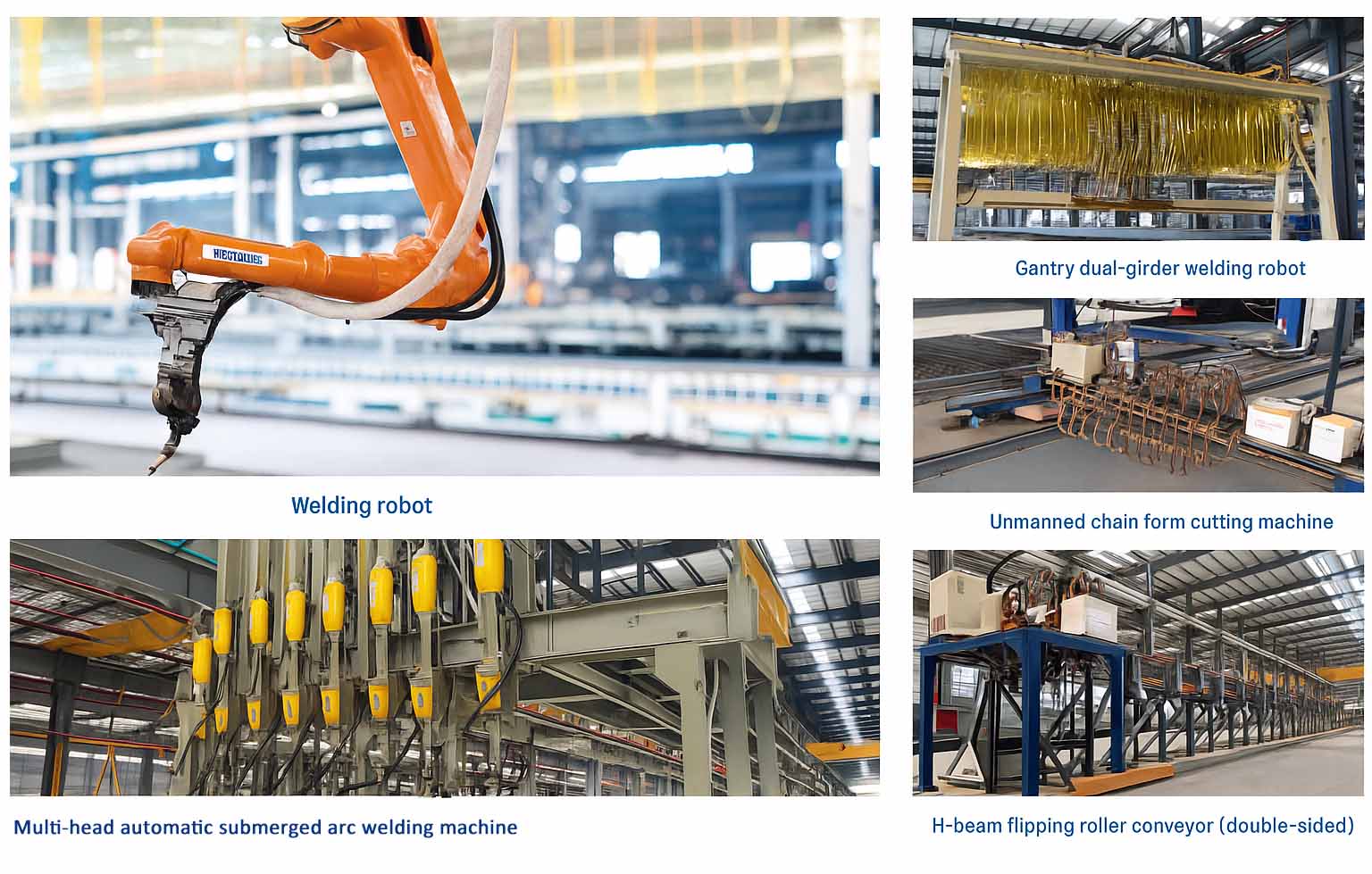

Professional steel structure production equipment

We have a complete steel structure production line and production equipment, including steel plate pretreatment production line, cutting machine, crane, welding machine, CNC bending machine, CNC flat drilling machine, robotic intelligent welding workstation, etc.

Powerful manufacturing capabilities - intelligent manufacturing

FAQ

1. What are ALC wall panels made of?

ALC (Autoclaved Lightweight Concrete) wall panels are made from cement, lime, quartz sand, and aluminum powder. These materials are autoclaved under high temperature and pressure to form lightweight panels reinforced with double-layer steel mesh for enhanced strength and durability.

2. Can ALC wall panels be customized for different building designs?

Yes. We offer fully customized ALC wall panels in various thicknesses, lengths, and finishes to match the design and structural requirements of modular buildings, prefabricated houses, and other construction types.

3. What are the main advantages of using ALC wall panels in modular buildings?

ALC wall panels are lightweight, fire-resistant, sound-insulating, and thermally efficient. They are easy to install and significantly reduce construction time compared to traditional masonry walls.

4. Are ALC wall panels suitable for both interior and exterior walls?

Yes. Our ALC wall panels can be used for both interior partition walls and exterior walls. With proper surface treatment, they offer excellent weather resistance and long-term stability for outdoor applications.

5. How are the panels installed and connected to the steel structure?

The panels are designed for easy installation. They are typically fixed to the steel structure using embedded connectors and sealants to ensure airtightness and structural integrity. Detailed installation guidance is provided with every order.

For any needs, please contact us. Our professional team and engineers will be happy to assist you.

Tags :

leave a message

Scan to Wechat/Whatsapp: